Categories: Perforated Metal

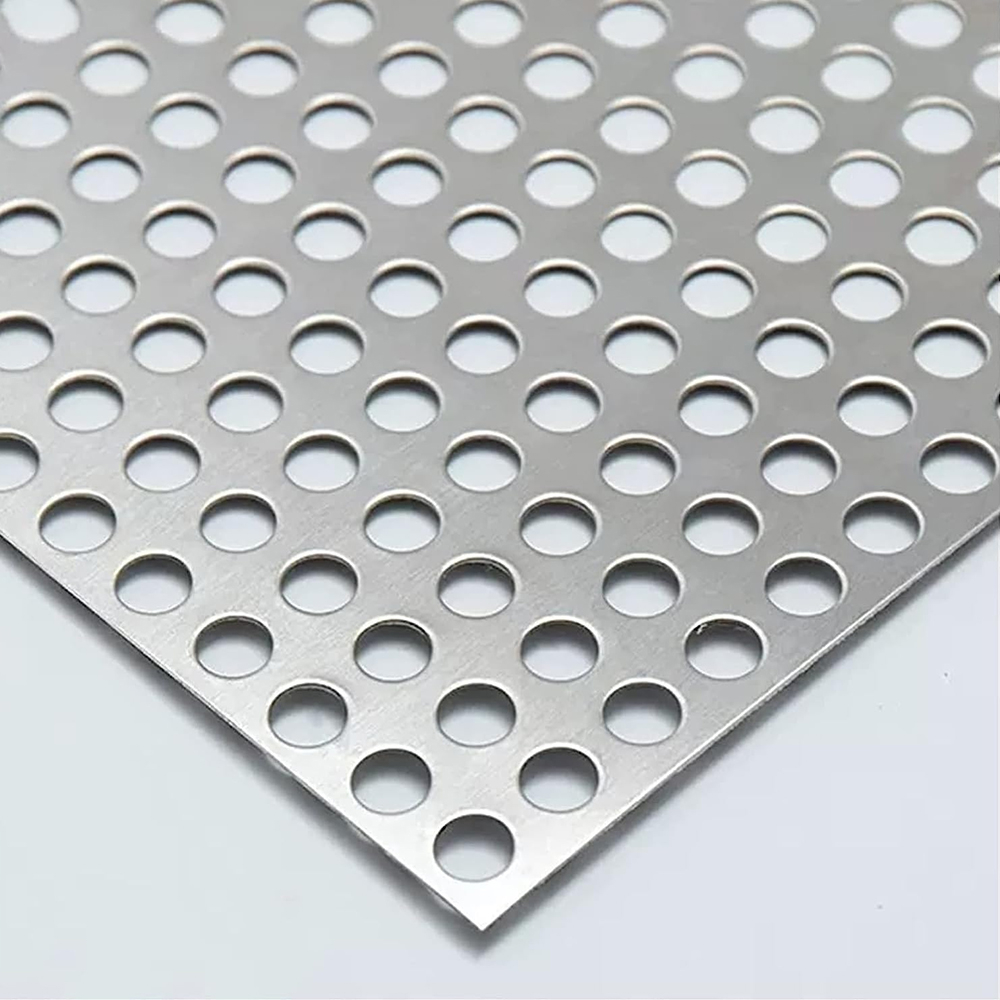

1.Perforated metal Definition:

Perforated metal is a mesh product formed by continuous stamping on metal sheets to form a series of holes, strips or decorative patterns. This material is widely used in architectural decoration, screening and filtration, ventilation and noise reduction, etc.

2.Perforated metal Features:

Perforated metal has uniform filtration holes, providing stable filtration effect; has a rigid structure and can provide strong support; corrosion resistance, acid and alkali resistance; stable filtration holes and strong resistance to deformation; excellent wear resistance; easy to cut and process.

3.Perforated metal Manufacturing process:

The manufacture of perforated metal usually uses cold stamping method, which is carried out on a stamping machine, especially using a wide belt production line. Other manufacturing methods such as liquid and laser cutting are also developing rapidly

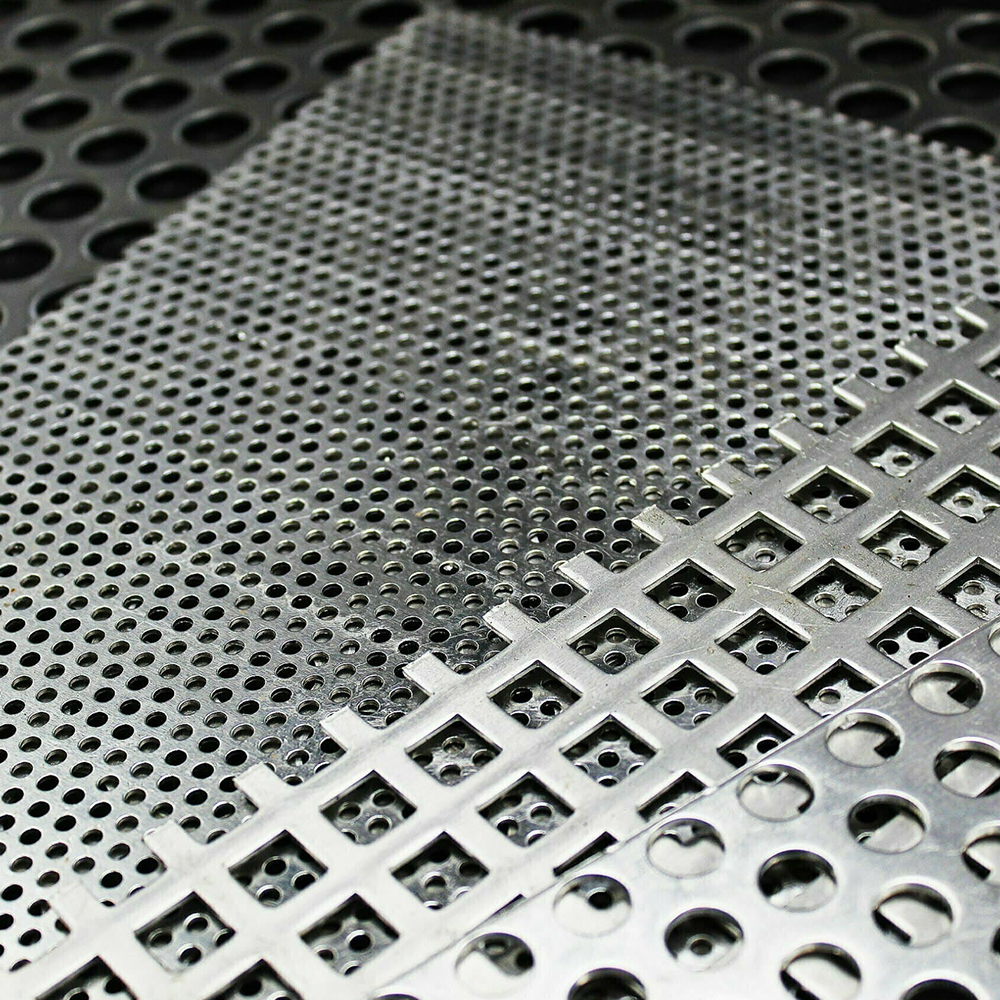

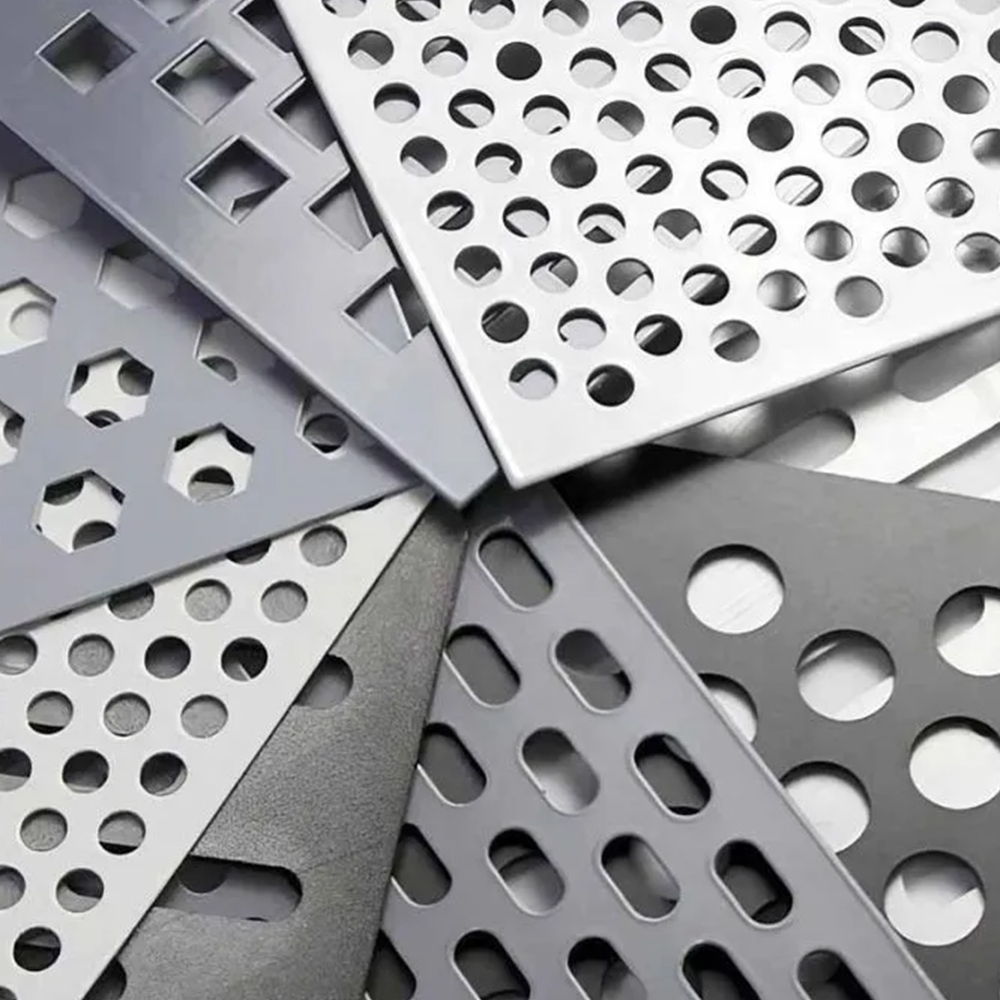

4.Perforated metal Specifications:

Some common technical data of perforated metal include thickness from 0.2-25mm, aperture 0.5-200mm, size 1000x2000mm or 1219x2438mm, or customized according to customer needs. Surface treatment includes polishing, powder coating, spraying

5.Perforated metal Environmental protection and sustainability:

Perforated metal materials (PMMs) are an important source of secondary raw materials that can be used in buildings, design elements and the production of other products, making them more environmentally friendly. The life cycle of PMMs can be extended by recycling, using or reusing, which includes methods such as construction technology, powder metallurgy, and permeable structures.

6.Perforated metal Economical:

The use of scrap metals can make the technical process of smelting metals less energy-intensive than obtaining products from ore, and significantly reduce harmful emissions into the atmosphere. Metals can be returned to the production process intact, especially steel, which can be recycled infinitely without losing quality.

7.Perforated metal Installation and maintenance:

Perforated metals are usually installed by screw or welding. Screw installation can be installed directly with self-tapping screws, or after pre-drilling the edges. Welding installation is usually used in construction projects that require post-painting treatment. After welding installation, if the perforated metal has been treated with anti-corrosion, additional anti-corrosion treatment is required to prevent corrosion at the welding points.

Anping County AOMIAO Metal Mesh CO.,LTD has manufacture metal mesh for 20years,our factory mainly manufacture Standard Expanded Meta,Flattened Expanded Metal,Expanded Grating,Perforated Metal,Serrated Steel Bar Grating,Press Locked Steel Grating,Flat Bar Steel Grating,Grip Strut Grating,we got ISO9001,ISO4001,BV certificate,SGS,etc.

Copyright © AOMIAO All Rights Reserved. Privacy Policy