Categories: Expanded Metal Mesh

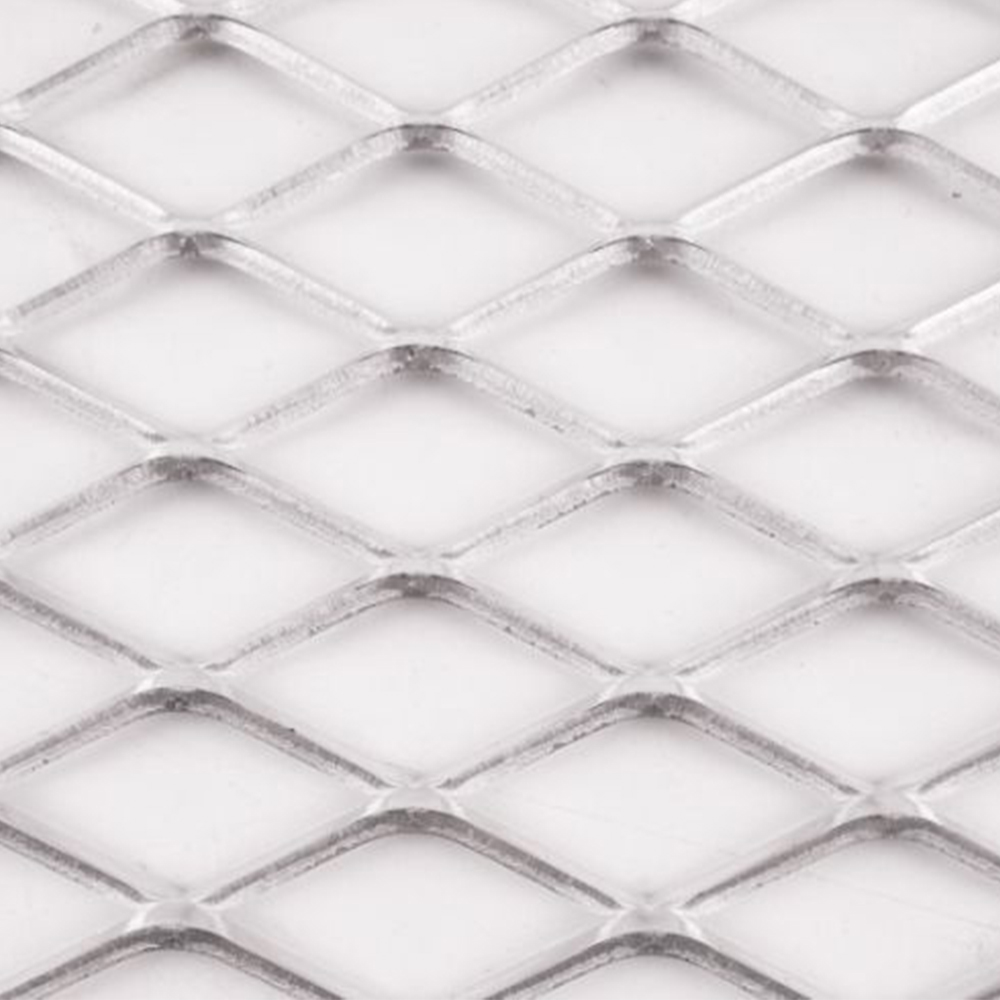

1.Standard Expanded Metal Mesh Definition and Characteristics:

Standard expanded metal, also known as raised expanded metal, is produced by simultaneously cutting and stretching metal sheets or coils. It has a raised diamond-shaped opening surface.

The raised ribs are angled with the original sheet plane, adding extra strength and rigidity. It also provides excellent anti-slip properties.

The surface of standard expanded metal mesh is raised, and compared to flattened expanded metal mesh, it has a slightly raised surface, which makes the material superior in terms of structural strength and grip properties.

2.Standard Expanded Metal Mesh Manufacturing Process:

The standard expanded metal mesh manufacturing process begins with a solid sheet passing through a pulling roller and entering a set of perforating shears. When the upper blade meets the straight fixed lower blade, the solid sheet is cut at right angles in the direction of the blade’s advance. After cutting, the sheet is stretched to form half of the first row of diamonds. The upper blade is then lifted and moved sideways, and the sheet is advanced again to form the second half of the diamond. These cutting, stretching and advancing operations are automated until the entire sheet is formed

3.Standard Expanded Metal Mesh Specifications:

Standard expanded metal mesh specifications include different thicknesses, mesh widths and lengths, which can be customized according to project requirements.

For example, carbon steel standard expanded metal mesh has specific specifications for parameters such as minimum thickness, nominal weight, design dimensions, opening size and overall thickness.

4.Standard Expanded Metal Mesh Application Areas:

Standard expanded metal mesh has a wide range of applications in multiple industries due to standard expanded metal mesh’s durability and versatility. It is commonly used in road fencing, platform and stair treads, machine guarding, etc.

In the construction industry, standard expanded metal mesh is used as a reinforcement material for concrete structures to provide additional strength

In industrial manufacturing, standard expanded metal mesh is used as machinery guarding, safety barriers and conveyor belt systems

In the automotive industry, standard expanded metal mesh is used to make grilles, radiator guards and air intake screens

In the security and fencing field, standard expanded metal mesh is used to make fences, gates and security screens

In HVAC and ventilation systems, standard expanded metal mesh’s open structure promotes optimal airflow, making it ideal for making air filters, grilles and diffusers

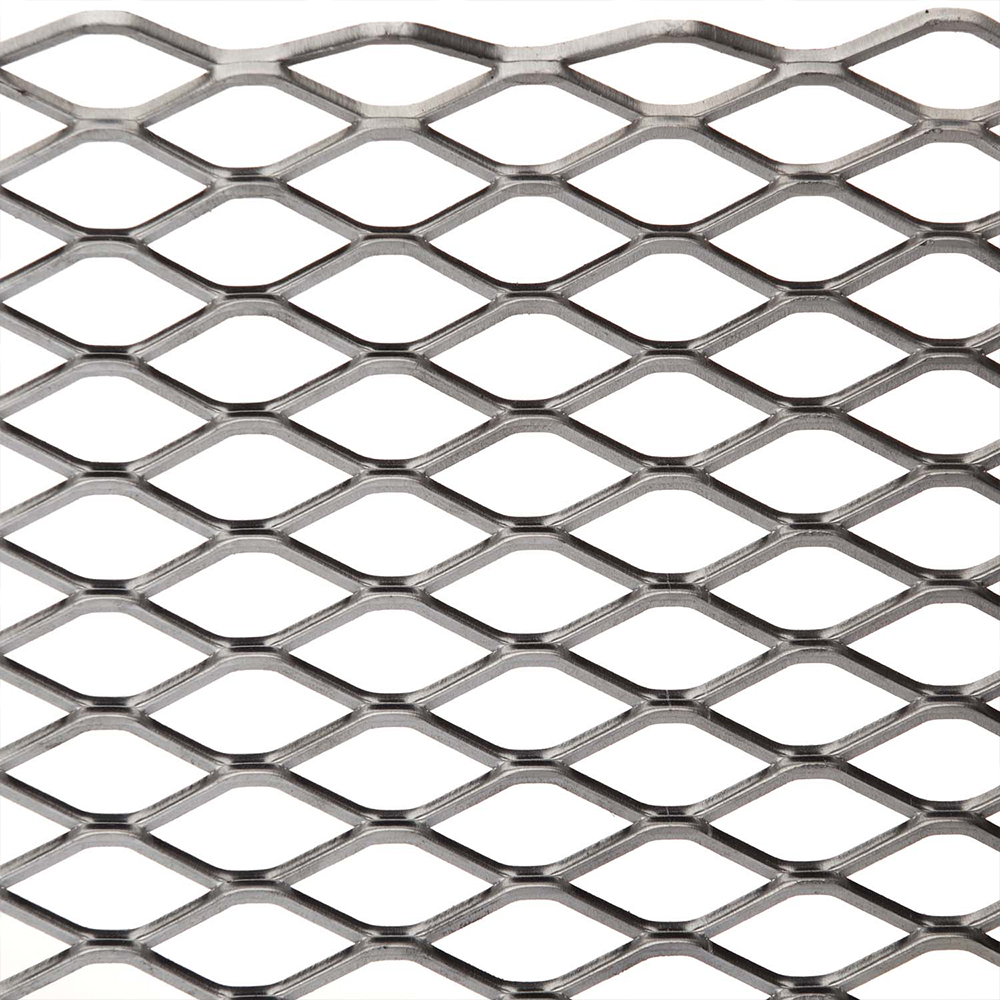

5.Standard Expanded Metal Mesh Materials and Specifications:

Standard expanded metal mesh can be made from a variety of materials, including carbon steel, galvanized steel and aluminum.

Standard Expanded Metal Mesh has a variety of mesh patterns such as diamond, fan, round, gothic and hexagonal, and new molds and customized mesh patterns can also be developed according to customer requirements.

6.Standard Expanded Metal Mesh Surface Treatment:

Standard Expanded metal mesh can be improved in durability and appearance through surface treatment processes such as electro-galvanizing and hot-dip galvanizing, powder coating.

7.Standard Expanded Metal Mesh Environmental Protection and Sustainability:

Standard Expanded Metal Mesh is a seamless, eco-friendly material with virtually no waste in the manufacturing process as the base metal is cut and stretched into its final shape.

Standard Expanded Metal Mesh can be used for lightweight structures and energy-efficient buildings, meeting sustainability goals.

Anping County AOMIAO Metal Mesh CO.,LTD has manufacture metal mesh for 20years,our factory mainly manufacture Standard Expanded Meta,Flattened Expanded Metal,Expanded Grating,Perforated Metal,Serrated Steel Bar Grating,Press Locked Steel Grating,Flat Bar Steel Grating,Grip Strut Grating,we got ISO9001,ISO4001,BV certificate,SGS,etc.

Copyright © AOMIAO All Rights Reserved. Privacy Policy